DPD3.1

Incredibly fast and portable

thermal-conduction vacuum dryer.

Using a combination of thermal-fin technology for heat and a vacuum, the DPD3.1 dramatically shrinks drying times. And since it requires less power, heaters and the vacuum pump use a fraction of the energy of conventional hot-air dryers. Plus, quicker drying times mean you can use a smaller hopper.

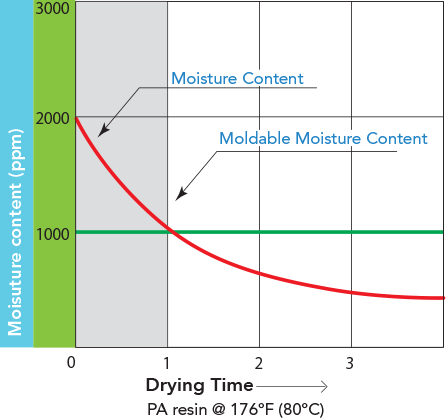

Low-temperature, thermal-fin conduction and vacuum technology dries fast.

The DPD3.1 vacuum dryer achieves dramatically short drying times at lower temperatures than conventional dryers. In a vacuum, water boils at low temperatures. Using thermal-fin technology to apply heat to the pellets while in a vacuum, water literally boils off and is sucked out of the pellet interior.

Sophisticated functionality.

Programmable functions enable you to preset operations, monitor settings, view progress and make changes effortlessly.

Improved product quality

The DPD3.1 shortens the time required for drying by using the energy-saving high-thermal conduction method. This also improves the effect of gas removal which in turn reduces the frequency of maintenance on the mold surface, aiding in overall part quality.

More safety power

A thermal temperature protection circuit as well as valve safeties are standard features.

Decreases mold maintenance

The vacuum drying process pulls out much of the contamination that can clog pins and vents. As a result, molds may run for longer periods without the need for cleaning.