MJ3 Dryer / Loader

Drop moisture levels faster.

Start molding sooner.

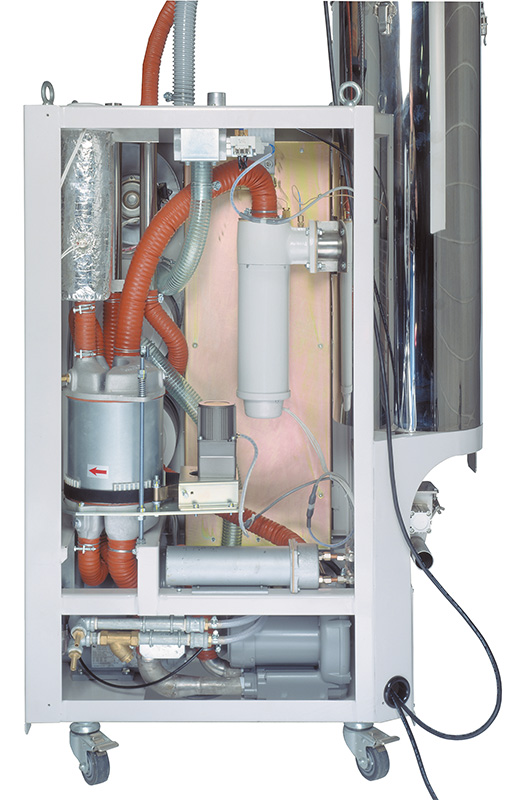

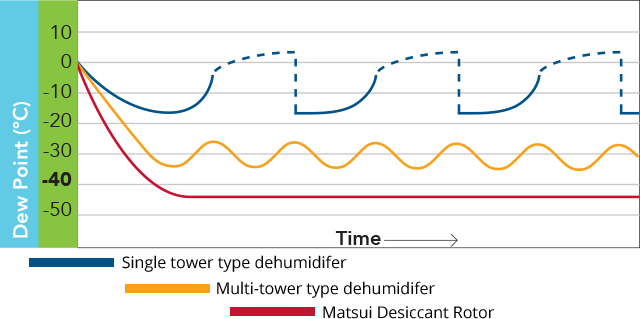

The MJ3 portable desiccant dryer/loader’s advanced resin drying technology drops moisture levels in a fraction of the time. Then it keeps resin a consistent, rock solid -40ºF dew point all the way to its core. And it does it faster and more consistently than the competition, so you can start molding faster.

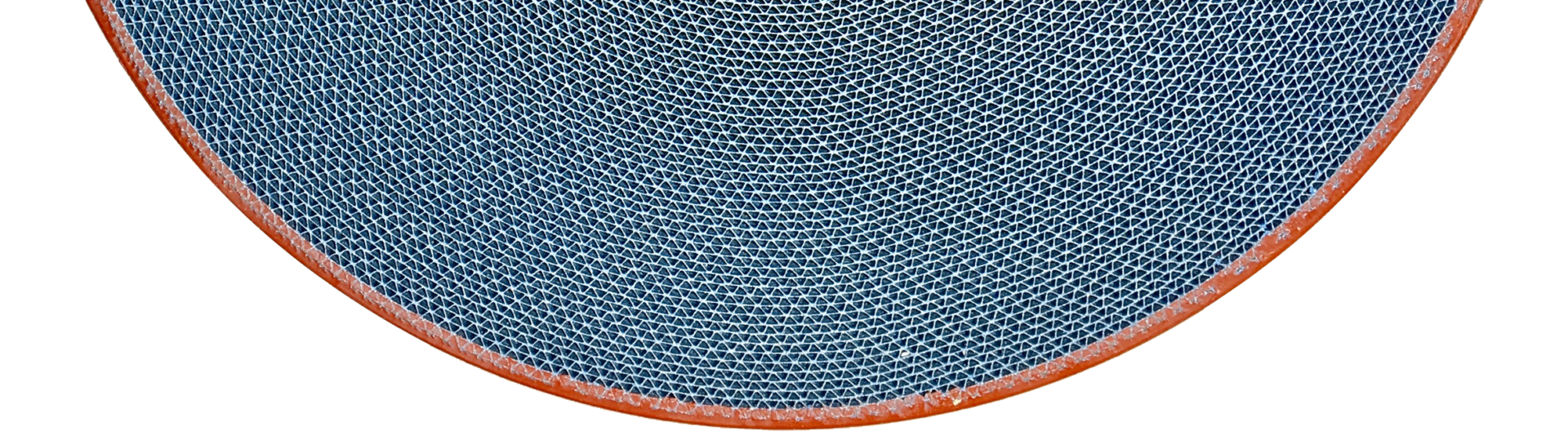

Our "Honeycomb" desiccant wheel.

Sweet.

Matsui took a queue from nature and created the “honeycomb” desiccant wheel technology, then perfected it for decades. The spinning wheel is constantly presenting fresh, thirsty desiccant as moist air travels through every channel. As the wheel travels, “wet” desiccant is dried and ready to absorb moisture again, and again, and again. Engineered to perform maintenance-free for years, desiccant wheels routinely still hold dew-point to -40ºF after 15 years.

Resin dries fast. And stays dry.

Matsui’s desiccant rotor technology dries resin extremely fast. The desiccant rotor's large area of contact effectively absorbs at high temperatures, drying resin in half the time while stabilizing dew points at a constant -40ºF.

Intuitive "touch & go" programming.

The simplified controller makes it easy to set up the MJ3 to handle a single or multiple presses.

Point-to-point dry air conveying.

The MJ3’s drying hopper is designed to create mass flow with no short-pass. It is equipped with a programmable loader, which releases measured amounts of resin at specific intervals.

Pellets are conveyed using warm, dry air and delivered for the next loading cycle on a just-in-time schedule. This keeps pellets at the optimum moisture level from dryer to molding machine, maximizing performance.

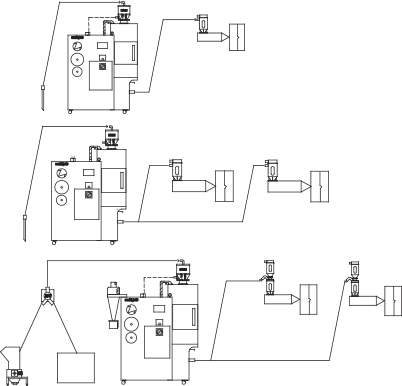

Extremely versatile, this efficient portable unit can be configured for a single machine, multiple machines, and to receive and dry a blend of regrind and virgin material.

Our customers understand it best.

MJ3

| Model MJ3 | 15U | 25U | 50U | 75U | 100U | 150U | 200U | 300U |

|---|---|---|---|---|---|---|---|---|

| Drying hopper (lbs.) | 33 | 55 | 110 | 165 | 220 | 330 | 440 | 660 |

| Hopper volume (ft3) | 0.88 | 1.4 | 3 | 4.4 | 6 | 8.8 | 12 | 17.6 |

| Dew point (°f) | -40 (86°F, 75% RH) | |||||||

| Airflow (cfm) | 23 | 23 | 47 | 47 | 70 | 70 | 106 | 165 |

| Temperature range (°f) | 176-320 | |||||||

| Drying blower (kw) | 0.42 | 0.42 | 1.15 | 1.15 | 1.75 | 1.75 | 2.6 | 3.45 |

| Regeneration Blower (kw) | 50 | 50 | 94 | 94 | 94 | 94 | 200 | 200 |

| Drying heater (kw) | 2.1 | 2.1 | 4 | 4 | 6 | 6 | 7.5 | 12.4 |

| Regeneration heater 230/460 (kw) | 1.9/2.5 | 1.9/2.5 | 2.4/3.2 | 2.4/3.2 | 3.0/4.0 | 3.0/4.0 | 5.8/7.7 | 9.0/9.0 |

| Absorbent / Desiccant | Zeolite-rotor | |||||||

| Desiccant drive motor (kw) | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Hose size: drying (inches) | 1.5 | 1.5 | 2 | 2 | 2 | 2 | 2.5 | 3.5 |

| Hose size: regeneration (inches) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.5 | 3.5 |

| After-cooler flow (gpm) | No water needed. unit uses air cooling coil. | 2.7 | 2.7 | 5.3 | 5.3 | |||

| Water connection (inches) | No water needed. unit uses air cooling coil. | 0.5 | ||||||

| Primary Full Load Amps 230/460 | 20/13A | 31/18A | 38/22A | 57/33A | 86/44A | |||

| Secondary control circuit | AC-100 Volts, 1-Phase | |||||||

| Compressed air (psi) | 70 | |||||||

| Primary conveying distance (ft) | 30 | 30 | 30 | 30 | 30 | 30 | 50 | 50 |

| Secondary Conveying Distance (ft) | 15 | 15 | 15 | 15 | 15 | 15 | 30 | 30 |

| PVC Conveying hose (inches) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 2 |

| Conveying blower (kw) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.6 | 2.6 |

| Approximate dimensions (inches) | 38x21x70 | 38x21x80 | 46x25x83 | 46x25x95 | 51x25x91 | 51x25x106 | 58x29x100 | 67x36x100 |

| Weight (lbs) | 470 | 490 | 630 | 650 | 730 | 770 | 1100 | 1550 |

| System Control | Auto Tuning Microprocessor | |||||||

| System Protection | Overheat Alarm, Low-Temp Alarms, Reverse Phase Alarm, Blower-Overload Alarms, Dry & Regn Sensor Alarm, Conveying Abnormals Alarms, Automatic Cool Down Mode | |||||||

| System Features | Energy Saving Hopper, Solid State Relays, Primary & Secondary Conveying, Line Purge, 15-Year Desiccant, Cyclonic Dust Collection, Dry Air Conveying for Secondary Circuit (not available for 15U or 25U) | |||||||

| Available Options | Weekly Timer, Alarm Output, Alarm Lamp, Regrind Ratio Valve, Dew Point Meter, Aero Power Hopper, ARV Material-Dust Collector, Second Machine Conveyance | |||||||