MC5

Portable water unit heats faster

so you start molding sooner

Introducing the new MC5, the next generation in mold temperature controllers. It reaches temperature settings faster, so as it moves from machine to machine you are ready to mold sooner. And it has a bigger, feature-packed, user-friendly control panel, yet has a small footprint, so it slips in and out of the smallest places.

More power = more productivity

With a more powerful heater, pump and sensor, the MC5 reaches target temps within 1° of set point fast, and takes samples 4 times/second to maintain optimum levels throughout production. So you can mold more parts faster and better, boosting productivity and your bottom line.

Intuitive, touch-and-go programming

MC5’s large touchscreen lets you store up to 64 different temperature settings, preset operations, monitor progress, detect errors, improve maintenance and more. The G1 panel comes standard; the more advanced G3 panel is available as an optional upgrade.

Maintenance teams love MC5, too

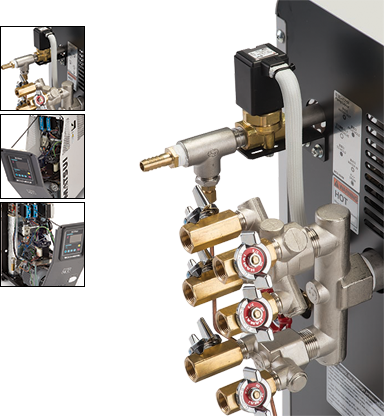

That’s because the solenoid valve is conveniently located on the outside of the cabinet where it’s easier to reach, and solid state relays in heater controls and other critical components are made of stainless steel.

To service the inside, just remove four screws and lift off the base plate. A safety disconnect switch prevents accidental start-ups.

Small footprint

One of the smallest, lightest, most mobile mold temperature controllers, MC5 fits into tight production spots where others cannot. And with casters built into the base, it’s easy to move from machine to machine.

12 models to choose from

The new MC5 comes in three sizes with both standard (G1) and advanced (G3) designs for use with low temperature (up to 203°) or high temperature (up to 248°) water. G3 units offer even more programming features as standard.

Heater and pump sizes on the new MC5 are optimized for performance, minimizing energy consumption. The unit’s precision control software and technologically advanced circuitry reduce heater “on” time up to 8%, increasing your energy savings.

Standard (G1) units of the new MC5 are in stock and ready to ship. They come with everything needed for installation, including 2-way or 4-way manifolds and ball valves. There’s also an adjustable pressure bypass valve allowing you to tailor and optimize performance for different jobs.

New standard features of MC5:

- Stores up to 64 temperature settings

- Timed switching (10 sets of 10 temperature values)

- Temperature control programming

- Displays estimated setup temperature waiting time

- Heating and cooling error detection

- Programmable slow cooling

- Variable temperature control programming

- Programming to stop unit automatically at a preset temperature

G3 units also have:

- Set value switching

Other standard features:

- Digital temperature display

- Reverse-phase detection

- Operation monitoring

- Alarm indication of pump overload, abnormal sensor, low level, low/high temperature, machine maintenance

- Automatic pressure relief

- Heat-resistant water level detection switch

- Pressure gauge

- One-touch display of set values on control panel

- Remote operation of start/stop

- Automatic air venting at start-up

Standard deatures of MC5 Control Panel:

- Intuitive, user-friendly operation

- Easy to read LCD display visible even in bright lighting

- Displays PV, set values, alarm status, operation status, overloads/errors, estimated setup temperature waiting time

- Option to display error history

- Function for programming temperature control

G3 units also have:

- Calender function

- SPI or MODBUS communications board

- Can display flow rate and pressure (requires sensor)

MC5

| model MC5 | MC5-25L / MC-25H | MC5-55L / MC5-55H | MC5-88L / MC5-88H |

|---|---|---|---|

| power supply voltage | 230V or 460V, 3ph 50/60 Hz | ||

| power usage (kVA) | 5.5 | 8 | 11.8 |

| breaker capacity | 20 | 30 | 40 |

| media* | Fresh Water (soft water) | ||

| maximum water temperature | 203ºF / 248ºF | 203ºF / 248ºF | 203ºF / 248ºF |

| cooling capacity (kW)/pressure (Mpa) - 50ºF | 2.4 / 3.3 | 2.9 / 4.1 | 3.6 / 4.9 |

| cooling capacity (kW)/pressure (Mpa) - 86ºF | 7.2 / 9.8 | 8.6 / 12.4 | 10.7 / 14.7 |

| cooling capacity (kW)/pressure (Mpa) - 140ºF | 14.5 / 19.6 | 17.2 / 24.7 | 21.4 / 29.5 |

| heater capacity | 4kW | 6kW | 9kW |

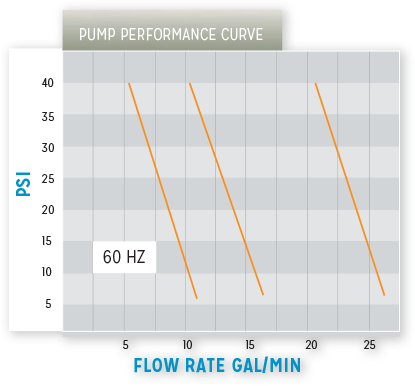

| pump flow rate (Gal/min) - 50Hz | 7.9 | 12.5 | 20.4 |

| pump flow rate (Gal/min) - 60HZ | 10.2 | 14.8 | 22.7 |

| pump motor (HP) | 0.4 | 0.8 | 1.3 |

| pump performance | Refer to pump performance chart (page 2) | ||

| water level detection | electrode sensor or float switch | ||

| temperature controller input | k-type thermocouple | ||

| water supply port | ø 10.5 hose nipple & strainer | ||

| water drain port | ø 10.5 hose nipple | ||

| medium feed and return port | 3/8" x 2 ball valves | 3/8" x 4 ball valves | 3/8" x 6 ball valves |

| drain port | 1/4B purge | ||

| approx. dimensions w/l/h (inches**) | 9.1 x 17.7 x 20.6 | 9.1 x 19.6 x 22.2 | 9.1 x 22 x 26.5 |