JL4 Loader

Vacuum hopper loading system.

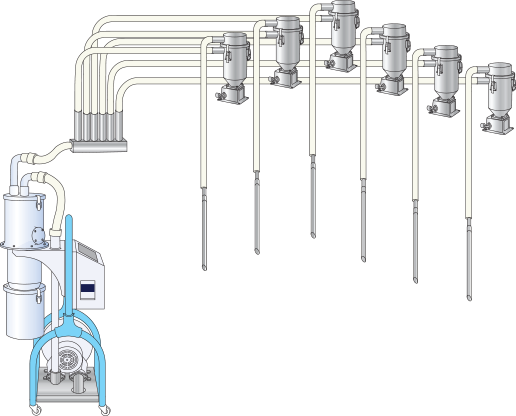

Feed up to 6 machines!

Portable, powerful and engineered for efficiency, the JL4 easily meets the needs of your demanding production line.

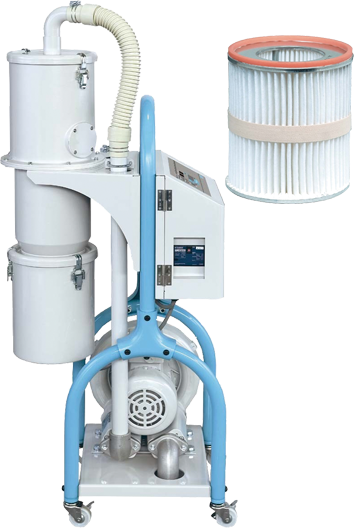

The Jet Loader effectively removes dust using a unique two-tier dust collection system that consists of one filter in the hopper and one at the vacuum pump. The JL4 also helps dramatically increase conveying capacity while using half the power consumed by conventional loaders.

Feed up to 6 machines at once!

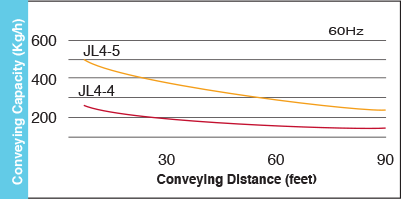

These powerful loaders can send material throughout the plant with a minimum of pressure loss. Conveying capacities vary with shape and density of material, piping material and bends in the pipeline, suction nozzel type, etc.

Easy to maintain

You can quickly purge accumulated resin dust by simply unclipping a cap. No time-consuming tear down to clean and re-assemble. Included as standard is a cyclonic fines-separator to efficiently remove dust and dramatically reduce the time spent cleaning the machine. Powerful and effective, it also reduces material entering the filter, extending the life of the filter and time between cleanings.

In addition, the new filter design minimizes clogging and extends the filter life, increasing the units efficiency

Compact at ground level

The JL4 is compact enough to sit beside the press and is designed for the user to use the controls and check filters at ground level. No more climbing on top of injection decks and risking broken limbs as with common "motor loaders" sitting atop the press! Also, since the JL4 uses a 3-phase ring compressor, you'll know that it can handle loading capabilities for years and years to come, unlike light-duty 100-volt brush-motor loaders.

Smart design

The JL4 includes a filter timing light that informs you when to inspect the filter for clogs. An alarm and warning lamp are also available. The unit is equipped with a quiet, efficient motor to help you keep manufacturing noise levels to a minimum.

Touchpad programming

An easy-to-use touchpad simplifies programming, enabling you to preset operations, monitor settings, view progress and make changes effortlessly.

JL4 = Jet Loader 4th Generation

| Model JL4 | 4VC | 5VC | 6VC | 7VC |

|---|---|---|---|---|

| max static pressure psi (kPa) | 2.6 (18) | 3.0 (21) | 3.5 (24) | 4.6 (32) |

| max airflow rate cfm (m3/m) | 99 (2.8) | 99 (2.8) | 134 (3.8) | 215 (6.1) |

| max output hp (kW) | 1.5 (1.15) | 2.0 (1.50) | 3.4 (2.55) | 6.1 (4.6) |

| conveying hose | 1.5 in | 2.0 in | 2.5 in | |

| vacuum hose | 1.5 in | 2.5 in | ||

| jet clone (receiver) | JC-3(3L); JC-6(6L); JC-9(9L) | JC-18 | ||

| suction nozzle (standard) | 1.5 in | 2.0 in | 2.5 in | |

| gaylor suction nozzle (optional) | 1.5 in | 2.0 in | 2.5 in | |

| power supply | AC 208, 230, 460 Volts, 60Hz 3PH | |||

| full load amps 230v/460v | 10A / 5A | 20A/10A | 40A/20A | |

| control voltage | AC120v | |||

| compressed air req. | 45~110 PSI / .07 cfm | |||

| approx. weight lbs | V: 105 / VC: 115 | 152 | 200 | |

| approx. dimensions (in) | 14 x 21 x 47 | 14x21x47 | 21x23x47 | 22x24x48 |

| vc dust box capacity f3 (l) | .25 (7L) | |||

| standard features | cyclone fines separator, buzzer with alarm code, blower, overload-protection, filter cleaning reminder, controller malfunction alert. | |||

| available options | 2-6 way conveying, oversized cyclone, collection cup (15L), mini vacuum hopper, aero power blending hopper, jsv regrind ratio valve, output signal for batch valve, flashing alarm light | |||