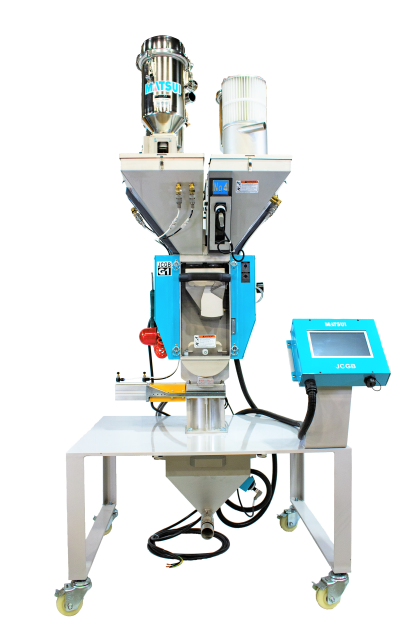

JCGB

Gravimetric Batch Blender

Small size, Huge ability

The new Jet Color Gravimetric Blender or simply JCGB™, is a gravimetric-batch blender that aims to be the best cost-effective blender in the industry! Blended materials can be supplied to the injection molding machine or extruder and used in any application environment, providing customers with benefits such as more efficient production, ease of use, and resource-savings.

Accurate Blending in a compact size!

Blend up to four materials, simply and accurately without breaking the bank! The JCGB is one of our easiest blenders to operate, with a sleek and efficient design. The blender takes advantage of a vertical valve to ration out each material with accuracy, and adds the ability to quickly remove the material hopper for cleaning.

Material-changes are a breeze!

The JCGB has four lightweight material hoppers that can be lifted off for easy cleaning without any tools! Its a small on stature, but mighty on useful features.

Flexible Placement

The JCGB dimensions are ideal for feed-throat mounting, or machine-side on a frame, giving you plenty of options to utilize as your press needs change.

Easy & Versatile Controller

A tethered 7-inch color touchscreen interface allows for easy operation- both for local access or through a VCN connection for remote monitoring and setting access.

Easy maintenance

Detachable material hoppers make cleaning simple. A material drain-chute can be installed to quickly change materials. In the manual purge mode, all actuators can be simply engaged to drain materials easily. All items can be removed / re-installed fast- without tools, to get the JCGB quickly back into production.

JCGB

| Model: JCGB G1-064 | Specifications | ||||||

|---|---|---|---|---|---|---|---|

| Power Supply | Voltage | 100~120 VAC, 60Hz 1-phase | |||||

| Apparent Power | 150VA | ||||||

| Air Supply | Pressure | Consumption | 0.08 bu /min | ||||

| Maximum Processing Capacity | 132 lbs. (60kg) / hr. | ||||||

| Measurement Type | Gravimetric | ||||||

| Measuring Points | 4 | ||||||

| Supplying Method | Vertical valve x 4 | ||||||

| Single Batch Volume | 500g | ||||||

| Hopper | Volume | Virgin | 10L | ||||

| Regrind | 10L | ||||||

| MB | 10L | ||||||

| Additive | 10L | ||||||

| Measuring Hopper | Volume | 1.8L | |||||

| Blending section | Method & Volume: | Mixing by pneumatic rotary actuator | Effective Volume = 2L | ||||

| Materials | Virgin | Pellets: cut strand approx. 1.5 to 4mm dia. 4mm long. Square pellets: approx. 1.5 to 4 mm | |||||

| Regrind | Materials that do not bridge the safety mesh (40mm x 40mm openings) excluding miscuts with an apparent specific gravity of 0.3 to 0.5 | ||||||

| Standard Features | 7-inch color touch panel, USB External Memory, Multi-languages: English, Japanese, Chinese, Alarm & Auto-Run Signals | ||||||

| Communications | MODBUS / TCP | ||||||

| Remote Operation | Remote operation by VNC connection | ||||||

| Optional Features | Alarm light w/ Buzzer, Floor Frame, Low-level alarm, Air Cleaning Gun | ||||||

| Heat-Resistance | Machine Protection: 248 F / 120 C | ||||||

| Outer Dimensions (inches) | 21"w x 21"d x 28.5"h | ||||||

| Weight (lbs) | 110 lbs. (50Kg) | ||||||