DMZ2

Stand alone desiccant drying.

Start molding sooner.

The DMZ2 portable desiccant dryer can be part of your central loading system or serve multiple hoppers. It’s advanced resin drying technology drops moisture levels in a fraction of the time. Then it keeps resin a consistent, rock solid -40ºF dew point all the way to its core. And it does it faster and more consistently than the competition, so you can start molding faster.

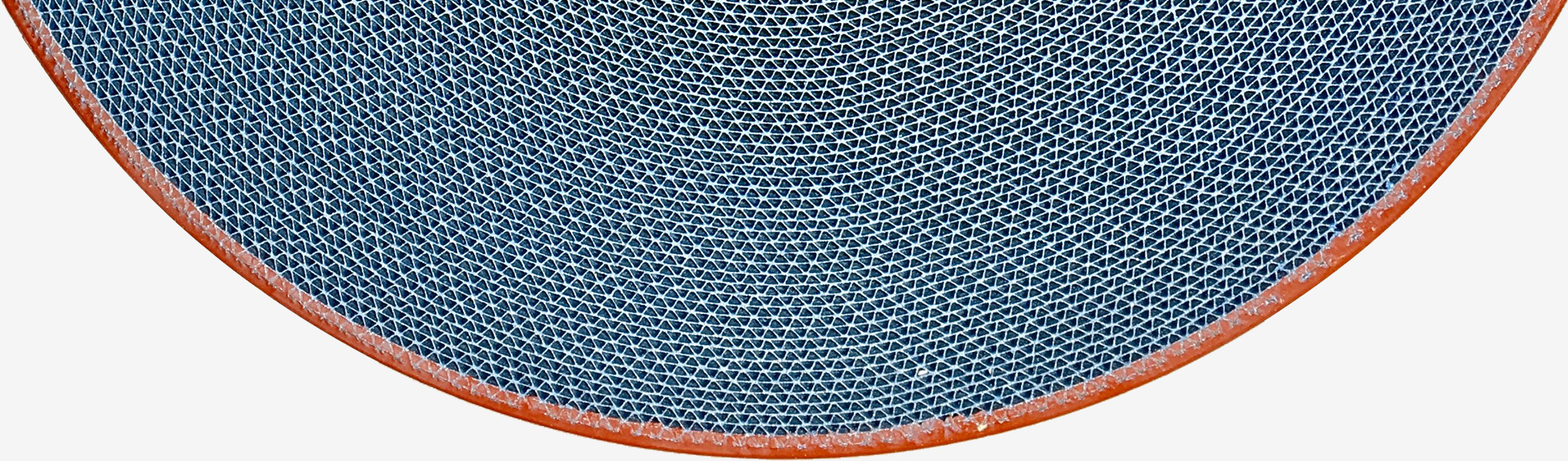

Our "Honeycomb" desiccant wheel.

Sweet.

Matsui took a queue from nature and created the “honeycomb” desiccant wheel technology, then perfected it for decades. The spinning wheel is constantly presenting fresh, thirsty desiccant as moist air travels through every channel. As the wheel travels “wet” desiccant is dried and ready to absorb moisture again, and again, and again. Engineered to perform maintenance-free for years, desiccant wheels routinely still hold dewpoints to -40ºF after 15 years.

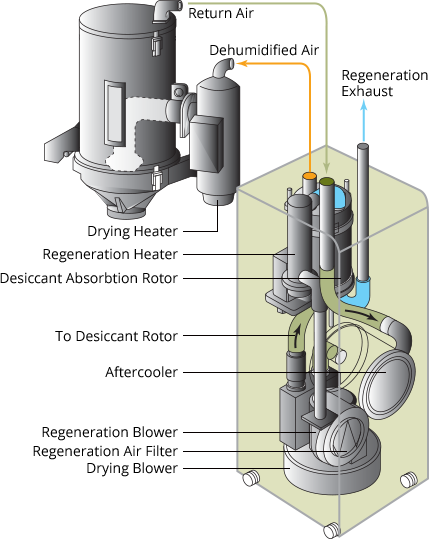

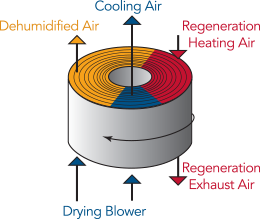

Spin, absorb, repeat

This is how it works. The rotor rotates through the various air flows. Heat dries the desiccant, the drying blower sends moist air through the desiccant and exists as dehumidified air. Then air cools the desiccant making it ready to remove moisture. And it does it reliably year after year after year.

Ideal for PET bottle production

The DMZ2 maintains a stable IV and a low AA levels, and brings moisture content below 50 ppm. It can dry PET in as little as 3 hours and has a throughput up to 1500 kg/hr and larger.

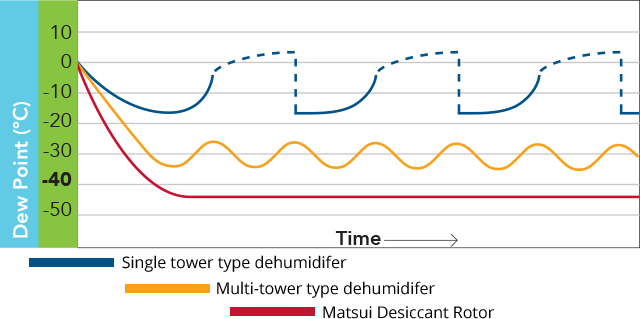

Resin dries fast. And stays dry.

Matsui’s desiccant rotor technology dries resin extremely fast. The desiccants large area of contact effectivley absorbs at high temperatures, drying resin in half the time while stabilizing dew points at a constant -40ºF.

Intuitive "touch & go" programming.

The new touch-screen programming makes it even easier to set up the DMZ2 to handle a single or multiple machine.

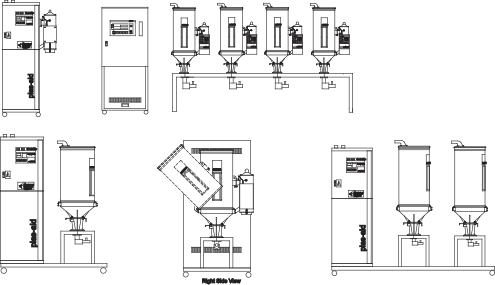

Central loading or multiple hoppers.

Maximum performance in minimal space. The DMZ2 can be part of your central loading system, or handle multiple hoppers. So you get maximum performance with a small footprint.

Routine maintenance can be performed form the front of the system, quickly and easily.

Insulated stainless steel construction prevents heat loss, and while drying resin in half the time, it saves hours of energy with every material change.

DMZ2

| Model DMZ2 | 40U | 80U | 120U | 170U | 240U | 500U | 700U | 900U |

|---|---|---|---|---|---|---|---|---|

| Dew Point (°f) | -40 | |||||||

| Airflow (cfm) | 23 | 47 | 70 | 106 | 165 | 294 | 412 | 530 |

| Available Hoppers (lbs) | 33/35 | 110/165 | 220/330 | 440 | 660 | 880/1100 | 1540 | 2420/1980 |

| Hopper Volume (ft3) | .88/1.4 | 3.0/4.4 | 6.0/8.8 | 12 | 17.6 | 24/30 | 41 | 53/65 |

| Drying Blower (kw) | 0.5 | 0.85 | 1.55 | 1.75 | 2.55 | 2.55x2 | 2.55x3 | 6.3x2 |

| Regeneration Blower (w) | 50 | 94 | 94 | 420 | 1150 | 1150x2 | 1150x3 | 750 |

| Drying Heater (kw) | 1.5 (2.1H) | 2.4 (4.0H) | 3.3 (6.0H) | 4.0 (7.8H) | 6.0 (12.4H) | 12.4 (23H) | 18 (30H) | 24 (40H) |

| Regeneration Heater (kw) | 1.5 | 2.4 | 3.1 | 5.8 | 7.7 | 6.6x2 | 6.6x3 | 23.1 |

| Absorbent | Zeolite-rotor | |||||||

| Absorbent Motor (w) | 25 | 25x2 | 25x3 | 90 | ||||

| Aftercooler Flow (gpm) | 1.5 | 3.7 | 4 | 4 | 5.2 | 10.5 | 16 | 26.5 |

| Aftercooler Connection (in) | 3/8" | 1" | 1" | 1.25" | ||||

| Control | Microprocessor w/PID Heating | |||||||

| Auto Start Timer | Range: 10-min to 99hrs 50min | |||||||

| Alarm & Protection | Overheat, Thermal Trip, Reverse Phase, Automatic Cool Down | |||||||

| Power Supply (volts) | 230V or 460V 3ph, 60Hz | |||||||

| Maximum Temperature | 266ºF (H-356ºF) | |||||||

| Breaker-amps (230/460V) | 20/16 | 32/16 | 32/20 | 40/32 | 56/29 | 125 | 175 | 225 |

| Hi-Temp Model | 20/16 | 32/16 | 40/20 | 45/26 | 73/37 | 125 | 200 | 225 |

| Weight (lbs) | 264 | 352 | 440 | 760 | 800 | 1518 | 1980 | 2420 |

| Approximate Dimensions (inches) | 17x22x52H | 20x28x53H | 20x28x53H | 31x35x72H | 31x35x72H | 33x51x88H | 33x67x88H | 56x58x88H |

| Available Options | Weekly Timer, Dew Point Meter, Filter Alarm, Floor Frame, V-Box, Insulated Hopper | |||||||