MCX2

Wide-range Temperature Controller

Expand your process-flexibility!

Introducing the new MCX2, for complete flexibility in mold temperature controllers. Featuring dual-zone heating and water-cooled chilling circuits combined into one sleek unit, it can process those hard to achieve temperatures between 46 to 194 Fahrenheit (8 ~90 C).

The MCX2 can independently control two separate zones processes, (such as mold-cavity and core) so you can dial in temperatures easily. It also is portable enough to move from machine to machine so you are ready to mold anytime, for total versatility. It has a bigger, feature-packed, user-friendly 7-inch touch panel, dual-zone controls, high-accuracy and a compact design making it one of our most versatile temperature controllers ever!

Wider Temp-Range = More Flexibility

The MCX2 can control two zones (Zone 1 & Zone 2) independently, using highly efficient heaters, pumps and sensors, plus an integrated water-cooled chilling-circuit. The unit can be easily piped into your cooling-tower piping or factory chiller-circuit. The MCX2 reaches target temps within +/- 0.5 of set points with great accuracy and ease. So you can mold more parts faster and better, boosting productivity and your bottom line. Why limit your temperature process ability? Now you don't have to!

Intuitive, touch-and-go programming

MCX2's large 7" touchscreen lets you store different temperature settings, preset operations, monitor progress, detect errors, improve maintenance and more. Standard MODBUS communication protocol [RS-485] makes system & mold-cell integration a breeze!

Control the flow!

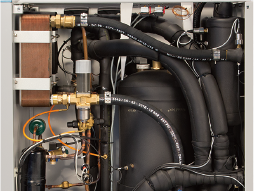

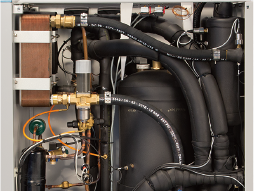

All medium flow valves are conveniently located on the outside of the cabinet where they're easy to reach and connect, solid-state relays for heater controls and other critical components are made of industry-grade materials.

Intuitive Controls

The user screens have many process and status views that allow for easy and complete monitoring of the MCX2, and its features.

High-Grade Construction

The chiller circuit, heater and pump sizes on the new MCX2 are optimized for performance, footprint, while minimizing energy consumption. The internal component are of high-grade stainless steel, brass and other high-grade materials to maximize long-life, and minimal servicing to keep your process running.

MCX2

| MCX2-G3 | 03 | 04 | 06 | 03D | 04D | 06D | |

|---|---|---|---|---|---|---|---|

| Power supply | Voltage | AC230V / 460V /60Hz 3ø | |||||

| Apparent power | 12.9 kVA | 16.7 kVA | 18.9 kVA | 20.6 kVA | 21.8 kVA | 24.0 kVA | |

| Breaker capacity | 50A / 25A | 60A / 30A | 75A / 40A | ||||

| Condenser cooling water | Flow rate (27°C) | 30 L/min | 45 L/min | 60 L/min | 30 L/min | 45 L/min | 60L/min |

| Flow rate (35°C) | 45 L/min | 60 L/min | 75 L/min | 45 L/min | 60 L/min | 75 L/min | |

| Pressure | 0.15 - 0.60 MPa | ||||||

| Medium | Clean water | ||||||

| Operating Temperature range | 47~194°F / 8~90°C | ||||||

| Cooling capacity (50Hz) | 46°F / 8°C | 7.4 kW | 11.2 kW | 14.8 kW | 7.4 kW | 11.2 kW | 14.8 kW |

| 59°F / 15°C | 9.2 kW | 13.8 kW | 18.3 kW | 9.2 kW | 13.8 kW | 18.3 kW | |

| 68°F / 20°C | 10.6 kW | 16.0 kW | 21.2 kW | 10.6 kW | 16.0 kW | 21.2 kW | |

| Control temperature (60Hz) | 46°F / 8°C | 8.5 kW | 12.9 kW | 16.7 kW | 8.5 kW | 12.9 kW | 16.7 kW |

| 59°F / 15°C | 10.5 kW | 15.9 kW | 20.6 kW | 10.5 kW | 15.9 kW | 20.6 kW | |

| 68°F / 20°C | 12.2 kW | 18.4 kW | 23.8 kW | 12.2 kW | 18.4 kW | 23.8 kW | |

| Heater capacity | 6 kW | 9 kW | 6 x 2 kW | ||||

| Medium tank | 23L | ||||||

| Refrigerant gas | R410A | ||||||

| Compressor output | 2.25 kW | 3.38 kW | 4.5 kW | 2.25 kW | 3.38 kW | 4.5 kW | |

| Circulation pump output | 0.75 kW | ||||||

| Pipe connections diameter | Medium feed & return port | G1 (25A) | G1 - 1/4 (32A) | G1 x2 (25A x2) | G1 - 1/4 x2 (32A x2) | ||

| Supply water port | G1/2 (15A) | ||||||

| Overflow | G1 (25A) | ||||||

| Cooling water inlet port | G1 (25A) + filter is standard equipment Cooling water outlet port | ||||||

| Cooling water outlet port | G1 (25A) | ||||||

| Cooling water filter | Single filter | ||||||

| Outer dimension | Width | 17.71 in. / 450mm | |||||

| Depth | 41.3 in. / 1049mm | ||||||

| Height | 56.2 in. / 1427mm | ||||||

| Product weight | 529 lbs. / 240 kg | 540 lbs. / 245 kg | 595 lbs. / 270 kg | 606 lbs. / 275 kg | |||

| Alarm display | Medium drop, Pump- Compressor overload, Cooling water shortage | ||||||

| Overheat, Sensor failure, High pressure, Low pressure, Freeze prevention. | |||||||

| Pressure gauge | Control panel digital indication | ||||||