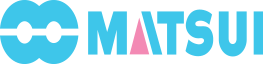

JCW2-i

Intelligent mixing, automatic flow

optimization & resin-demand forecasting

The JCW2-i gravimetric blender combines incredibly accurate blending technology with intelligent metering and forecasting to help you maximize quality and reduce energy and waste. It senses changes, automatically adjusts, and keeps production moving as demand changes.

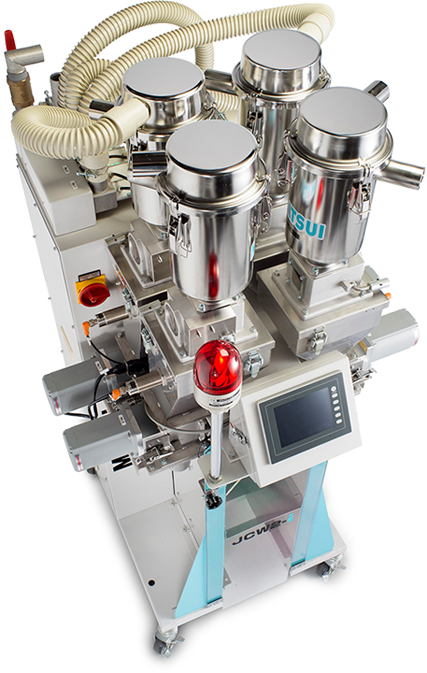

Intelligent mixing.

Feed optimization software, coupled with demand forecasting signals, reduce resin waste by as much as 99%. Flow is automatically regulated based on your injection mold machine‘s status. Minimizing material usage helps reduce cleaning time and labor when materials or colors are changed.

It works automatically

The JCW2-i optimizes blender performance without additional input. Even with a material change, the JCW2-i automatically detects and alters measurements to accommodate the new material. Simple.

A smaller footprint

The JCW2-i is nearly half the footprint of previous units, while maintaining a maximum capacity of 319 lbs/h. This is accomplished by integrating measuring and conveying into the unit. The intelligence software keeps batches smaller and maximizes mixture uniformity.

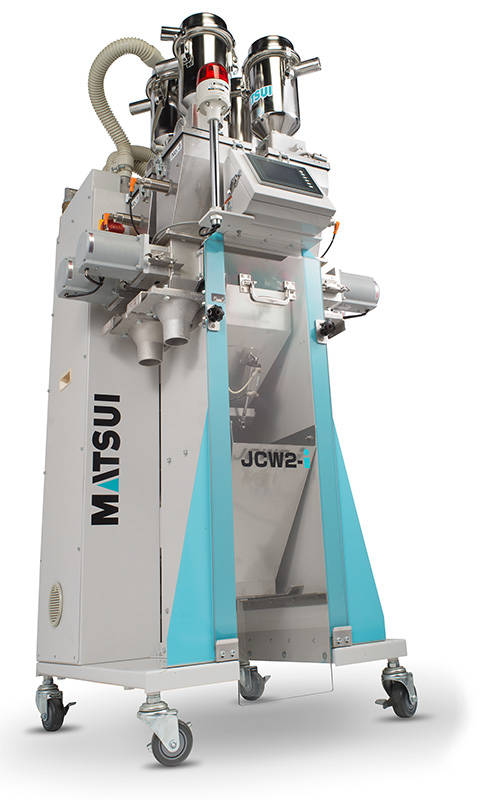

Simple-to-use interface

Technology is only as good the people who have to use it. We made it simple, using a straight-forward touch-screen interface.

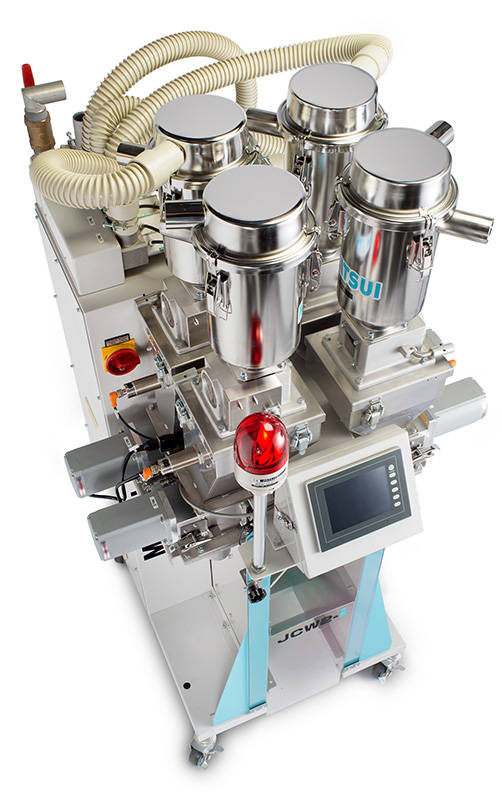

Easy maintenance

Smooth, polished hopper surfaces make cleaning fast. Dust can be swept down to the hopper bottom where materials can be completely removed. The hopper and screw can be easily removed, wiped cleaned, and re-installed fast to get the JCW2-i quickly back into production.

JCW2-i

| Model JCW2-i-05 | APH | JB | |||

|---|---|---|---|---|---|

| Power Supply | Voltage | AC200/230V/460V 50/60Hz 3-phase | |||

| Apparent Power | Breaker Capacity | 5.15kVA 30A | |||

| Air Supply | Pressure | Consumption | 0.4MPa 1NL/min | ||

| Maximum Measuring Capacity | 70kg/h | 1.45kg/h | 145kg/h | ||

| Processing Capacity | 60kg/h | 140kg/h | 140kg/h | ||

| Measurement Type | Gravimetric | ||||

| Measuring Points | 4 | ||||

| Hopper | Volume | Virgin | 5 or 14L | ||

| Regrind | 5 or 14L | ||||

| MB | 5 or 11L | ||||

| Measuring Hopper | Volume | 12L | |||

| Charge Hopper | Volume | Custom Made | 3.5L | ||

| Measuring Range | Virgin | Screw Feeder F-50 ITO 100g or more | |||

| Regrind | Screw Feeder F-50 ITO 100g or more | ||||

| MB | Screw Feeder F-40 ITO 50g or more | ||||

| Screw Feeder F-25 ITO 2g or more | |||||

| Measuring Accuracy | Virgin | ±0.5% The blender starts by measuring the ingredient that is used in the smallest amount, then uses that actual measurement to adjust the set values for materials to be subsequently measured, such as primary materials and regrind. As a result, the measurement accuracy for the materials measured first the the minimum setting gradation of 1g or less. |

|||

| Regrind | |||||

| MB | |||||

| Materials | Virgin | Pellets: cut strand approx. 1.5 to 4mm dia. 4mm long. Square pellets: approx. 1.5 to 4 mm | |||

| Regrind | Materials that do not bridge the safety mesh (40mm x 40mm openings) excluding miscuts with an apparent specific gravity of 0.3 to 0.5 | ||||

| Volume per Batch | up to 1kg | Up to 3kg | Up to 3kg | ||

| MB Ratio | Up to 1000x | ||||

| Mixing Method | APH (Blending Hopper) | Mixing Drum | |||

| Effective Volume | 3L | 8L | 10L | ||

| Outer Dimension (inches) | 33w x 37.5d x 68h | ||||

| Weight (lbs) | 308 | 331 | |||