MJ5-i

Lose the moisture.

Save your energy.™

It’s a resin-drying, energy-saving, thinking machine. With the most advanced resin drying technology, the MJ5-i dries resin in a fraction of the time so you can start processing faster. Then it continuously monitors load demands and dials down energy consumption while keeping resin a consistent, rock solid -40ºF dew point all the way to its core. Make no mistake-this is the industry's flagship dryer.

It Thinks. Therefore it saves.

The MJ5-i uses Matsui Inteli-Dry Technology to ensure you use only the energy you need while at the same time keeping an unwavering eye on your desired dewpoint . When load demand slows, the MJ5-i knows. Inteli-Dry quietly draws down on energy use while smartly keeping the correct dew-point. When demand ramps up, Inteli-Dry snaps to and immediately meets the call for more.

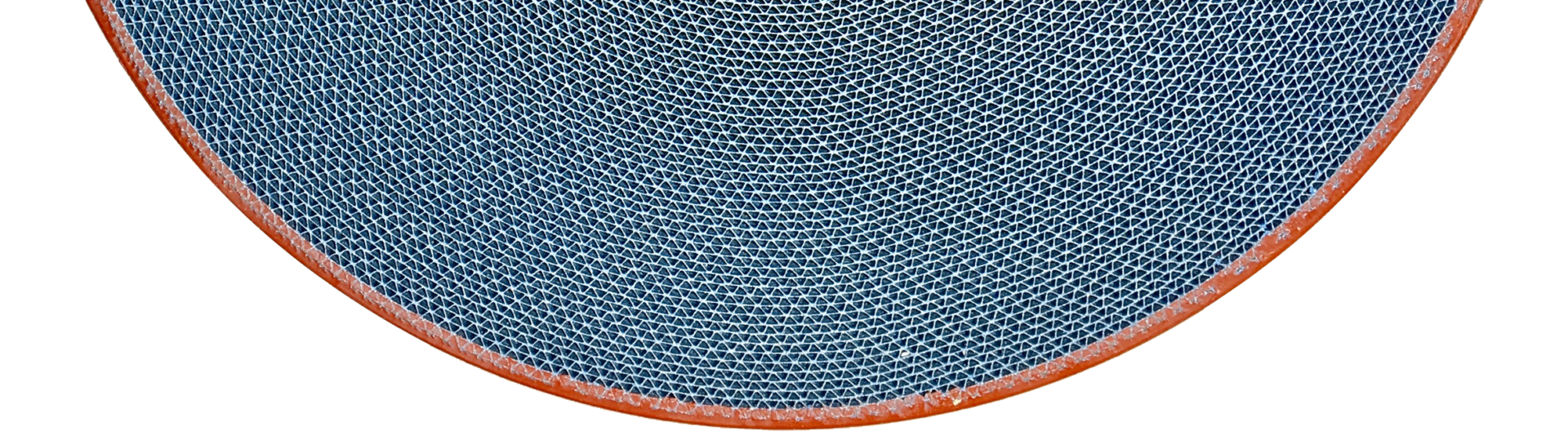

Our "Honeycomb" desiccant wheel.

Sweet.

Matsui took a queue from nature and created the “honeycomb” desiccant wheel technology, then perfected it for decades. The spinning wheel is constantly presenting fresh, thirsty desiccant as moist air travels through every channel. As the wheel travels “wet” desiccant is dried and ready to absorb moisture again, and again, and again. Engineered to perform maintenance-free for years, desiccant wheels routinely still hold dewpoints to -40ºF after 15 years.

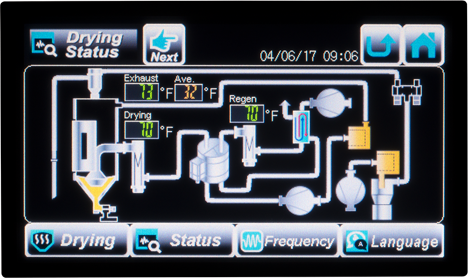

Intuitive "touch & go" programming.

The new touch-screen display makes it even easier to set up the MJ5-i to handle a single or multiple press hoppers. Save your program for future runs. Create new programs in a snap.

Little things that lead to bigger savings.

Large, easy-access, hopper door.

Front-of-system access simplifies routine maintenance.

Cyclonic filter captures dust before it reaches the main filter.

Removable feed line purge valve.

MJ5-i

| Model MJ5-i- | 150 | 350 | 650 | 1500 |

|---|---|---|---|---|

| Hopper Capacity (FT3) | 1.76 Ft3 / 30Kg | 3.53 Ft3 / 60 KG | 7.06 Ft3 / 120 Kg | 17.6 Ft3 / 300 Kg |

| Drying Temperature (¼F) | 140 - 320 | 158 - 320 | ||

| Dew Point | -40 (86¼F, 75%RH) | |||

| Dryer Blower (KW) | 0.28 | 0.42 | 1.15 | 2.55 |

| Dryer Heater (KW) | 2.1 | 2.4 | 5.4 | 10.8 |

| Regeneration Blower (KW) | 0.28 | 0.42 | 0.42 | 1.15 |

| Regeneration Heater (KW) | 1 | 2.1 | 3.1 | 5.8 |

| Absorbtion Tower Motor (W) | 25 | 25 | 25 | 25 |

| Conveying Blower (KW) | 1.5 | 2.55 | ||

| Conveying Blower - Primary Side (Ft.) | 30 | |||

| Conveying Blower - SECONDARY Side (Ft.) | 15 | 30 | ||

| Power Supply (V) | 230V 0r 460V, 3P 60 Hz | |||

| Operation Circuit Voltage | AC100V, DC24V | |||

| Superficial Electricity (KVA, 230V / 460V) | 7.6 / 7.6 | 9.6 / 9.5 | 15.8 / 15.0 | 31.0 / 29.8 |

| Breaker (A) | 30 | 30 | 50 | 100A / 50A |

| Air Supply Pressure (PSI) | 72 | |||

| Air Consumption (CFM) | 0.005 | 0.01 | ||

| Approximate Dimensions (Inches) | 44 x 24 x 53 | 47 x 24 x 87 | 59 x 25 x 99 | 75 x 36 x 106 |

| Weight | 595 lbs. | 640 Lbs. | 882 Lbs. | 1518 Lbs. |

| Drying Temp Control | PID Control Heater, Non-contact relay | |||

| Regeneration Temp Control | PID Control Heater, Non-contact relay | |||

| System Protection | Overheat protection (drying and regeneration temperature), Blower overload | |||

| External Control | External non-voltage contact [incoming current: 4.1 mA (DC 24V)] | |||

| System Features | Energy Saving Hopper, Solid State Relays, Primary & Secondary Conveying, Line Purge, 15-Year Desiccant, Weekly Timer. | |||

| Available Options | Dew-point indicator, Second Machine Conveyance, Different supply voltages (excluding UL/CE), Alarm Output, Alarm Indicator, Signal Wire Extension, Jet Selector (JSV-38, Transport Hose Length). | |||