MJ6-i Dryer / Loader

The New Standard in Drying & Loading is here!

Run Lights Out.

With more companies running "lights out" with 24/7 production lines, the MJ6-i was made to excel. The MJ6-i never sleeps-even when you do. With its refined energy-saving algorithms, responsive touchscreen display and smaller footprint, the MJ6-i is a resin-drying & loading thinking machine.

With the most advanced resin drying technology, the newly designed MJ6-i dries resin in a fraction of the time so you can start processing faster. It continuously monitors load demands and dials down energy consumption while keeping resin a consistent, rock solid -75ºF dew point all the way to its core.

Make no mistake-this is the industry's flagship desiccant wheel dryer & loader workhorse! Add in Matsui's industry-leading 6-Year warranty, and your peace of mind can soar like your profits.

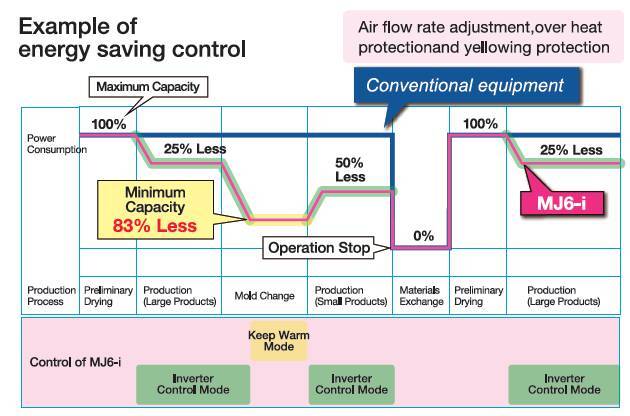

Energy Saved. Profits Gained.

The newly designed MJ6-i expands on its energy-saving predecessor MJ5-i, with decades of proven expertise. Matsui's i-Plas technology ensures you use only the energy you need- while at the same time keeping an unwavering eye on your desired results . When dryer load demand lessens for mold changes or idle presses, the MJ6-i knows. The constant i-Plas mode quietly and constantly reduces energy usage while smartly keeping the material desert-dry, with a constantly low dew-point. When demand ramps up, the MJ6-i revs up needed power immediately to ensure perfect results, every day. When combined with its standardly equipped self-loading and press-loading features, it makes for one powerful dryer / loader!

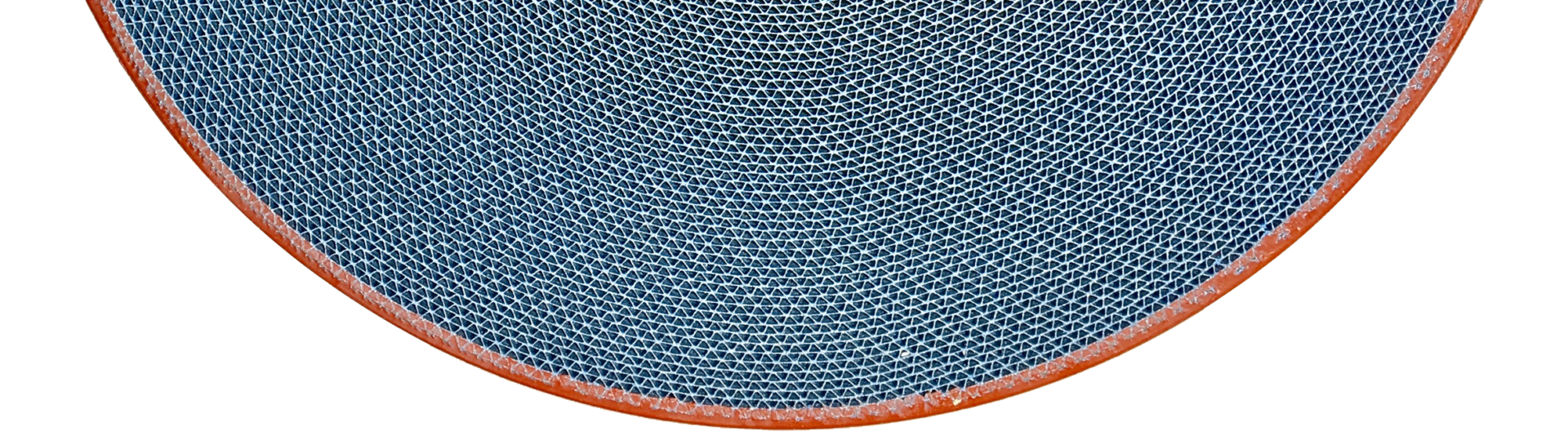

Our "Honeycomb" desiccant wheel.

Sweet.

Matsui took a queue from nature and developed the “honeycomb” desiccant wheel technology, then continued to perfect it for four decades. The spinning wheel is constantly presenting fresh, thirsty desiccant as moist air travels through every channel. As the wheel travels, “wet” desiccant is dried and ready to absorb moisture again, and again, and again. Engineered to perform maintenance-free for years, desiccant wheels routinely still hold dewpoint to -40ºF ~ -75ºF beyond 15+ years!

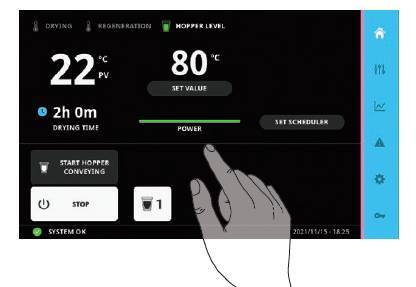

Newly designed Touchscreen

The new 7" touch-screen display was updated and redesigned to make settings smoother and simpler to use. The controller descriptions are easier to understand, has instant response, and can display all monitor modes, such as real-time data and alarm details and user-guidance. In addition it has a choice of languages to choose from. Its high-contrast screen makes viewing and setting as easy as "1,2,3".

Standard features that really stand out

Large, easy-access, hopper door.

Front-of-system access simplifies routine maintenance.

Cyclonic filter captures dust before it reaches the main filter.

Easy-clean feed line damper valve.

MJ6-i

| Model MJ6-i-G3- | 30 | 50 | 75 | 135 |

|---|---|---|---|---|

| Hopper Capacity (Ft3 / Kg) | 1.76 Ft3 / 30 Kg | 3.0 Ft3 / 50 Kg | 4.59 Ft3 / 75 Kg | 7.94 Ft3 / 135 Kg |

| Drying Temperature- F (C) | 158 ~ 320F (70~ 160 C) | |||

| Dew Point | -40F ~ -75F (86 % F, 75%RH) | |||

| Dryer Blower (KW) | 0.28 | 0.28 | 0.42 | 1.15 |

| Dryer Heater (KW) | 2.1 | 2.1 | 2.4 | 5.4 |

| Regeneration Blower (KW) | 0.28 | 0.28 | 0.28 | 0.42 |

| Regeneration Heater (KW) | 1.0 | 1.5 | 2.1 | 3.1 |

| Absorbtion Tower Motor (W) | 25 | 25 | 25 | 25 |

| Conveying Blower (KW) | 1.5 | |||

| Conveying Distance - Primary Side (Ft.) | 33 | |||

| Conveying Distance - SECONDARY Side (Ft.) | 16.4 | 30 | ||

| Power Supply (V) | 230V 0r 460V, 3P 60 Hz | |||

| Operation Circuit Voltage | AC100V, DC24V | |||

| Apparent Power (KVA, 230V / 460V) | 6.9 / 7.3 | 7.5 / 7.8 | 8.8 / 9.0 | 31.8 / 14.9 |

| Breaker (A) (230 / 460) | 20A / 15A | 20A / 15A | 30A / 15A | 40A / 25A / 50A |

| Air Supply Pressure (PSI) | 72 | |||

| Air Consumption (CFM) | 0.005 | 0.01 | ||

| Approximate Dimensions w/ Receiver Hopper (Inches) | 39 x 24 x 80.5 | 39 x 24 x 93.5 | 42 x 24 x 93.5 | 54 x 25 x 103.5 |

| Weight | 584 lbs. | 606 Lbs. | 639 Lbs. | 871 Lbs. |

| Drying Temp Control | PID Control Heater, Non-contact relay | |||

| Regeneration Temp Control | PID Control Heater, Non-contact relay | |||

| System Protection | Overheat protection (drying and regeneration temperature), Blower overload | |||

| External Control | External non-voltage contact [incoming current: 4.1 mA (DC 24V)] | |||

| Communication | Communication Points: (1) Port: EIA Spec. follows RS-485, Comm Speeds: 4800bps, 9600bps, 19200bps, 38400bps Protocols: SPICCP Ver. 4.0 (ANSI-X3.28 sub-type 2.4D1 Standard) MODBUS-RTU | |||

| System Features | Energy Saving Hopper, Alarm & Circuit Protection, Solid State Relays, Primary & Secondary Conveying, Dehumidified-Air Conveying Supply Line, 6-year Warranty, Weekly Timer. | |||

| Available Options | Dew-point indicator, 2~5-press Machine Conveyance, Different supply voltages (excluding UL/CE), Alarm Output, Alarm Light, Signal Wire Extension, Gas Trap, After-Cooler, Low-Level Alarm, Clear filter Lids, Digi-Peca Module, Acrylic Dust Cup, Regrind Ratio Valve (JSV-38/50). | |||