MGD

Portable hot-air dryer/loader.

Economical drying. Saves energy.

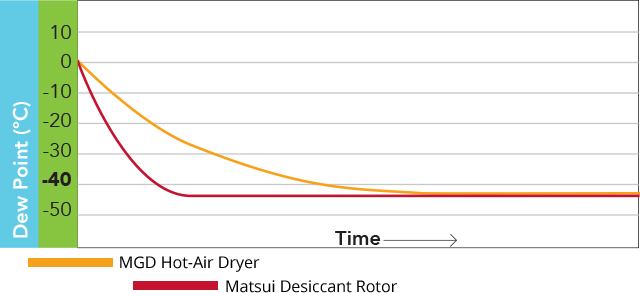

The power-sipping portable MGD hot-air dryer/vacuum loader uses significantly less energy and slightly longer drying times than our desiccant dryers to efficiently dry resin to optimum moisture levels.

Hot air technology keeps resin consistently dry.

Though slower than our desiccant rotor technology, Matsui’s hot-air drying technology is faster and maintains a more stable environment than other hot air dryers.

Virtually maintenance free.

The MGD is so simple in design it’s a snap to set up, and runs virtually maintenance free. Heater circuits with solid-state relays provide years of maintenance-free operation. Its efficient, streamlined design uses just a single blower and heater, reducing energy consumption. Routine maintenance can be performed from the front of the system, quickly and easily.

Point-to-point just in time conveying.

The MGD’s drying hopper is designed to create mass flow with no short pass. It is equipped with a programmable loader, which releases measured amounts of resin at specific intervals. Pellets are conveyed and delivered for the next loading cycle on a just-in-time schedule. This helps keep pellets at the optimum moisture level from the dryer to molding machine, maximizing performance and minimizing part defects.

Programming made simple.

An easy-to-use touchpad simplifies programming, enabling you to preset operations, monitor settings, view progress and make changes effortlessly.

MGD

| Model MGD | 15J | 25J | 50J | 75J | 100J | 150J | 200U | 250U | 300U |

|---|---|---|---|---|---|---|---|---|---|

| Hopper Capacity Cu. Ft. (I) | 0.99(28) | 1.55(44) | 3.18(90) | 4.41(125) | 6.00(170) | 8.83(250) | 12.36(350) | 15.01(425) | 17.66(500) |

| Stock Capacity *1 Lbs (kg) | 33(15) | 55(25) | 110(50) | 165(75) | 220(100) | 330(150) | 440(200) | 550(250) | 660(300) |

| Hopper Insulation | Glass Wool Insulation and Outer Panel | ||||||||

| Drying Temperature (°f) | 320ºF (180ºC)Max. | ||||||||

| Drying Blower (w) | 34 | 200 | 200 | 195 | 195 | 300 | 300 | 400 | 400 |

| Drying Heater (kw) | 2.1 | 4 | 5.4 | 6.3 | 7.5 | 12.4 | 17.1 | 19.8 | 19.8 |

| Heater Control | PID Control with SSR Contactor | ||||||||

| Power Supply Voltage | 230V/460V 3Phase 60Hz | ||||||||

| Breaker Capacity (230/460v) | 30A/15A | 30A/15A | 30A/15A | 30A/15A | 40A/20A | 50A/30A | 60A/30A | 100A/50A | 100A/50A |

| Compressed Air Requirement | 60 ~ 110 PSI (0.4 ~ 0.6MPa) 2.6GPM (10L/min) | ||||||||

| Conveying Blower | 1.1kW | 2.5kW | |||||||

| Primary Conveying Hose | 1.5”- x 15ft. (Option 1.5”- x 30ft.) | 2”- x 15ft. (Option 2”- x 30ft.) | |||||||

| #1 Secondary Conveying Hose | 1.5”- x 15ft. | 2”- x 15ft. (Option 2”- x 30ft.) | |||||||

| Option #2 Secondary Conveying | 1.5”- x 15ft. | 2”- x 15ft. (Option 2”- x 30ft.) | |||||||

| System Protection | Elec. and Mechanical Over-Heat, Reverse Phase Alarm, Automatic Cool Down Mode, Alarm Buzzer | ||||||||

| Approx. Shipping Weight lbs. (kg) | 330(150) | 375(170) | 460(210) | 500(230) | 530(240) | 600(270) | 880(400) | 1,280(580) | 1,350(600) |

| Approximate Dimensions (inches) | 34.6x23.8x 66.8H |

34.6x23.8x 76.6H |

39.4x28.5x 84.9H |

39.4x28.5x 96.7H |

43.2x30.7x 90.0H |

43.2x30.7x 105.4H |

57.1x27.8x 99.9H |

65.3x34.0x 94.0H |

65.3x34.0x 99.9H |

| System Features | Energy Saving Hopper, Solid State Relays, Primary Conveying, Secondary Conveying w/Line, purge valve | ||||||||

| Available Options | Weekly Timer, #2 Secondary Conveyance, APH Receiving Hopper for Secondary Convey | ||||||||